Vertical Presses for block pressing

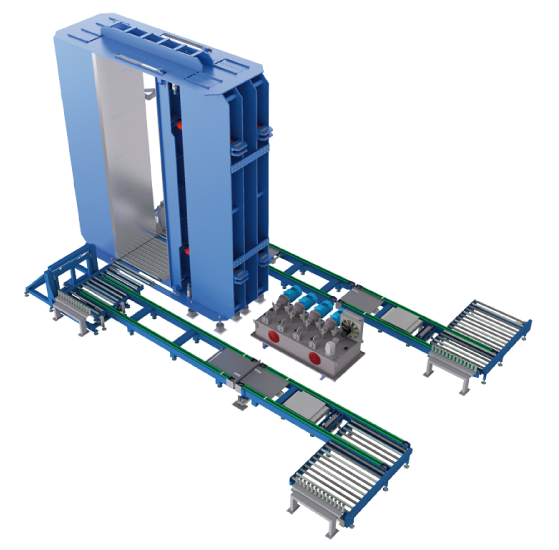

Vertical layout machines for lower space requirements

Designed for block compression up to 85% !

The Presses are specific for elasticizing EPS blocks from which obtaining sheets of low density soundproofing type called Trittschall (typically used in countries such as Germany and Switzerland for the soundproofing of floors) and as well at a higher density, between 15 ÷ 20 kg/m³ (0.93 ÷ 1.24 lb/ft³ ), in case even a certain grade of heat insulation is requested (eps sheets for application in the combined heat insulation and soundproofing of the wall surfaces).

The standard dimensions are foreseen for pressing blocks up to 8,0 x 1,4 x 2,6 m (315 x 55 x 102 in) with variable powers up to 400 metric tons (441 short tons USA) in function of the machine dimension in such a way to be able to ensure always a pressure on the block surface of at least 4 ÷ 5 kgf/cm² (57÷71 psi - lbf/in²).

Pressing speed is adjustable within 5 ÷ 20 mm/sec (0.197 ÷ 0.787 in/sec)

Opening speed is adjustable within 10 ÷ 40 mm/sec (0.394 ÷ 1.575 in/sec)

The possibility of programming multiple pressings with different grades of compression and different speeds of pressing and opening allows also to vary as required the compression cycles in function of the density and type of material with the aim of optimizing the acoustic insulation properties of the finished product.

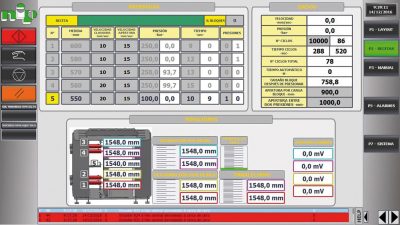

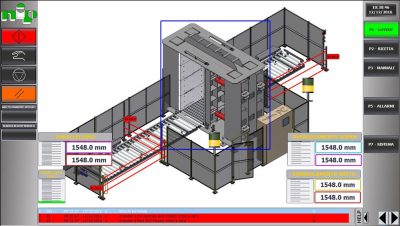

Modern and Advanced Control System

- Process Control by Recipes

- New WinCC Supervision System with 19” touch screen Siemens Industrial PC with SSD

- Fully integrable with customer ERP software for controlling the production

- Remote Control for distance support

Features

Machines are equipped with 4 special high pressure hydraulic cylinders acting on the 4 corners of the mobile plate and each of them receiving the proper calibrated amount of oil provided by 4 dedicated incremental range vane pumps through hydraulic proportional valves.

The parallelism of the mobile plate is electronically checked through 4 wire encoders (one on each corner of the mobile plate), and maintained within the acceptable tollerances by the sophisticated hydraulic proportional system that is adjusting the amount of oil provided to each cylinder and consequently the speed of each cylinder. This Advanced Technology of Control allows the machine to compress, in an effective way with no need of adjustments and without consequences on its mechanical apparatus both blocks with remarkable density variations and blocks with height and width smaller than the Maximum admitted by the machine (in case of height even down to half !) ensuring an easy and flexible machine operation.

Block Loading and Unloading Automated Systems are available to be combined with the Presses in order to answer to each Customer specific requirements of block handling in this specific step of the process.

Presses are also used to de-tension blocks after cooling in the storage allowing to eliminate the sheet/stripes deformation after cutting (useful for applications where high flatness is required).

De-tensioning Pressing process must be orientated in function on how the block is then cut in the subsequent cutting process.

Possible to manufacture very flexible machines which can press the block in any direction, useful especially for small compression de-tensioning procedures (≤ 10 ÷ 12% compressions) in function on how then the block has to be cut.